Search

“We got into dealership with JCB for eight districts in Tamil Nadu.â€

Senthil Bala, Chief Executive Officer, Surya Bala JCB, speaks on the current market trends and demands for CE in the regions they represent.

Opportunities galore

The construction industry across the globe is anticipated to present significant opportunities for construction equipment.

Gaining traction

Growing construction industry supported by global megatrend of urbanisation is expected to drive growth of the global aerial work platform market.

2021 will be a year of challenges and consolidations

Souma Ray, Director, Haulotte India shares his thoughts on the AWP market outlook and the company’s activities.

AWPs for safe and reliable operations

The post-pandemic conditions demand for safer and secure means of operations where AWPs will play a major role and will gain prominence in future.

Grading the Future

The current market conditions are tough for motor graders since the projects are not active due to the coronavirus impact.

Accessing New Heights

The use of aerial work platforms in India is still to gather momentum, in spite of the growing construction and urban infrastructure development. Increased awareness on safety among the end-users and a growing rental market are expected to drive the market in future.

Steering Growth

Growing urbanisation and mechanisation of manual jobs are driving the demand for compact equipment such as skid-steer loaders in India.

Cautiously Optimistic

The government's various initiatives on revival of infrastructure sector and favourable policies have driven the growth of Indian construction equipment market in the past 2-3 years.

Compact and powerful

With the growth drivers of urban and rural infrastructure markets opening up, mini construction equipment segment is looking for a renewed growth in the coming years.

We are positive about the future of mini excavators

Bobcat is currently offering three models of mini excavators in India. S Manjunath, General Manager-Sales, Doosan Bobcat India, elaborates more on the product range and market opportunities.

Looking for new growth avenues

The growth of crawler cranes market is stagnant with lagging demand from heavy lift applications. However, the market is expected to bounce back with the demand for medium capacity lift applications from the upcoming infrastructure development projects.

Lifting up Expectations

Gone are the days of slowdown and stagnation for mobile cranes market. Many equipment were seen idle with projects not taking off as expected.

AWPs: Safe working at heights

There is always risk involved in working at heights. Introduction of aerial work platforms has made it easy for workers perform well without any risk of falling, leading to timely completion of the work with higher productivity.

Telehandlers can gather a steady momentum in future

Telehandlers are versatile machines and have a wide range of applications across sectors. They are used in infrastructure, construction, mining, metals and minerals, logistics, ports and shipyards etc.

Paving on a High

Asphalt paver was developed by Barbar Green Co that originally manufactured material handling systems. In 1929, the Chicago Testing Laboratory approached them to use their material loaders to construct asphalt roads.

Imparting Versatility

Use of job-centric attachments converts conventional construction equipment into multipurpose machines, making them more productive, thereby ensuring better utilisation and job site economy. As rightly mentioned by industry veteran, Vipin Sondhi, Managing Director, JCB India Ltd, ?India is a country where jugaad is a way of life for providing engineered solutions for achieving desired objectives which are seemingly impossible many a time.

Backhoe Loaders Get a Rural Boost

Gone were the days when the backhoe loader market was exploding in all facets of India?s infrastructure development. All recognised suppliers were registering negative to flat trajectory growth since FY 2011.

Safe and Productive

The developed market saw the use of AWPs decades ago. Such machines were in demand by users, for two reasons: safety and speed of work.

Italian rental segment in building industry

The machinery and equipment hiring sector is growing in Italy, thanks to the ?Expo effect?. Estimates for the end of 2015 suggest a slight upturn which should consolidate the 2014 result (+0.7 per cent).

We need policy for smooth movement of cranes across state borders

In India it is becoming a trend to opt for newer cranes because the selection parameters are stringent and green initiative consciousness with multi nationals

We have good market share in 14-20 tonne excavators and road equipment

Volvo operates only through dealerships and being a local dealer was advantageous for me, since Volvo has its manufacturing facility and head office in Bengaluru, says Vinayak Nayak, Managing Director, Encore Heavy Machinery Pvt Ltd.

Most Popular Hydra Cranes

The market preference for Hydra cranes is tending towards eight-tyre based, front operator cabin and boom mounted wheel operated steer, Hydraulic mobile cranes. The pros and cons of this emerging trend are presented by Equipment India.

backhoe loaders:flat Growth

Backhoe loaders are passing through a challenging time for the past few years. Market is registering a flat growth with some indications that it is shrinking.However, now there is optimism among the leading players in the backhoe industry

Front-end Loaders Dominate Rentals

Market information on rental industry is extremely fragmented. No accurate or authentic data is available in the industry to support this activity. Having said that, as per available information gleaned from various sources, the industry size for 2-3 cu m bucket capacity front-end loader is estimated to be in excess of 20,000 units in India.

High Expectations

With growing safety awareness, the Aerial Work Platforms (AWPs), one of the best solutions to keep people safe, while working at heights, is poised for exponential growth in the near future.

Towering the Demand Curve

What lifting capacity range of TCs will dominate the demand for free standing, external and internal climbing configurations? Say Malik ?The 5-6T capacity TCs will remain as the most dominate category.

We need policy for smooth movement of cranes across state borders

In India it is becoming a trend to opt for newer cranes because the selection parameters are stringent and green initiative consciousness with multi nationals and even some government organisations

Accessing Heights, Safely

As the access equipment industry matures in India and users become more aware on the advantages of using such equipment over conventional practices of working at heights, the rental sector in India is poised for a very bright and promising future.

Rental segment will drive the demand for backhoe loaders

We are the authorised dealers for Terex Equipment in Mumbai, Thane and Raigad districts of Maharashtra. Terex in India operates in four different verticals: cranes, mining equipment (crushers and screens), earthmoving equipment, and aerial work platforms.

Government should encourage young and small entrepreneurs

We are a service-oriented company with sales, services and overhauling of various engines, transmissions, cranes and other heavy equipment. We are pioneers in sourcing hard-to-get parts and provide solutions to various issues pertaining to their machines.

Towering Tall

The real estate and power sectors will show a tremendous growth in the next 2-3 years. As per projections, the tower crane requirement will increase to 30-40 per cent in these two years. Current demand growth for tower cranes is mostly from realty sector.

The cranes need to be operator-friendly

Escorts has the exclusive distribution agreement for entire India with Comansa of Spain. Comansa being a pioneer in the field of flat-top cranes called topless cranes offer in the range 6T-64T.

Our products are technologically way ahead

The market is picking up. The market demand for 5T-6T tower crane is about 350 units; while the demand for 8T-10T is about 30-40 units and 12T and above is 25-30 units a year. The overall size is 400-450 units with approximate value of Rs 3,000-3,300 million.

Manufacturing industry boom to propel MHE market

Coming year, we are going to launch a couple of products in electric segment including a premium electric forklift, and a more efficient version of our stacker and battery-operated pallet truck. We are also planning to launch a new model of IC forklift, says MRV Johnson, Chief Marketing Officer, KION India.

Our efforts are to provide the best product and after-sales support.

In developed countries, there are legislations in place which ensure AWPs are used for working at heights. We strongly believe that such legislations should come in India too, says Souma Ray, Director, Haulotte India. Excerpts from the interview

Integrated Load Handling Solutions

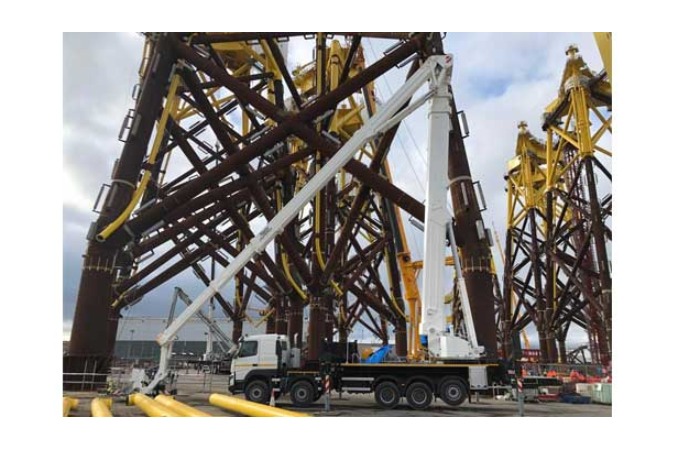

With a myriad of attachments, truck-mounted cranes have created niche applications segments with faster, safer and more productive solutions.Construction industry has been witnessing a shift towards using safer, more advanced technology, especially application-oriented equipment and machinery

Haulotte at bC India 2014

Haulotte Group, the people and material lifting equipment specialist, looks forward to giving its customers and partners a warm welcome on its stand to exchange views, communicate strategic commitments

STILL Number One

The focused thrust on infrastructure, manufacturing and agricultural sectors is expected to boost the demand for pick-n-carry cranes, which dominate the mobile crane market with over 80 per cent of total sales.

Piling Deep for Solid Growth

In a highly competitive market space hitherto rigged with challenge, the piling industry has responded positively by developing and launching advanced rigs. The piling technology with latest monitoring features could help increase productivity and reduce overall cost of a project.

Crawling Now, To Pick Up Soon?

Despite the muted demand due to lack of new projects in the power sector, the crawler cranes segment is expected to register good growth once the new projects are taken up after the general elections, writes Sudheer Vathiyath.India is a huge market for crawler cranes, especially higher capacity crawlers. This is mainly due to increasing demand in thermal power sector, nuclear power sector, steel plants, refinery expansions and wind power sector. However, the market has slowed down in the last tw

At Kobelco, we have set high standards for service.

Takeshi Miyashita, Director - Sales & Marketing, Kobelco: At Kobelco Cranes, safety is a major focus not only in the design stage but also throughout the lifecycle of cranes. Takeshi Miyashita, Director - Sales & Marketing, Kobelco, says that his company does not have a dealer-based business model and their engineers diectly service the customers.

Rentals will be the solution for the future

Knowledge and skill upgradation are vital and that is where Quippo plays an important role. We continuously devote time to upgrading knowledge; training is a continuous activity in our organisation.

In search of a strong foundation

Absence of big ticket projects such as greenfield power and steel plant projects, crashed out rental rates and surplus of idling equipment, and the cash flow crisis - the overall scenario of the foundation equipment market from the micro point of view seems to be grim, even though from the macro point of view few metro projects seem to have given a bit of relief to the industry.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com